All the intelligence is in a Texas Instruments low power MCU. It periodically reads data from a motion sensor chip, analyzes it and makes estimation about whether motorcycle is moving or not.

If the motorcycle is moving, MCU actuates a pump and a precise amount of oil is dispensed onto the chain every 30-180 seconds, depending on the user setting. The more often oil is dispensed, the more lubricated the chain will be.

A micro pump is used so as to dispense a precise amount of oil, regardless of the temperature or viscosity of the lubricant used. Some oilers on the market use pumps that can be damaged by certain lubricants. In a peristaltic pump, the fluid does not come into contact with pump's internal parts, hence user is free to use any lubricant he desires (engine, gear and very thin lubricants were used during testing).

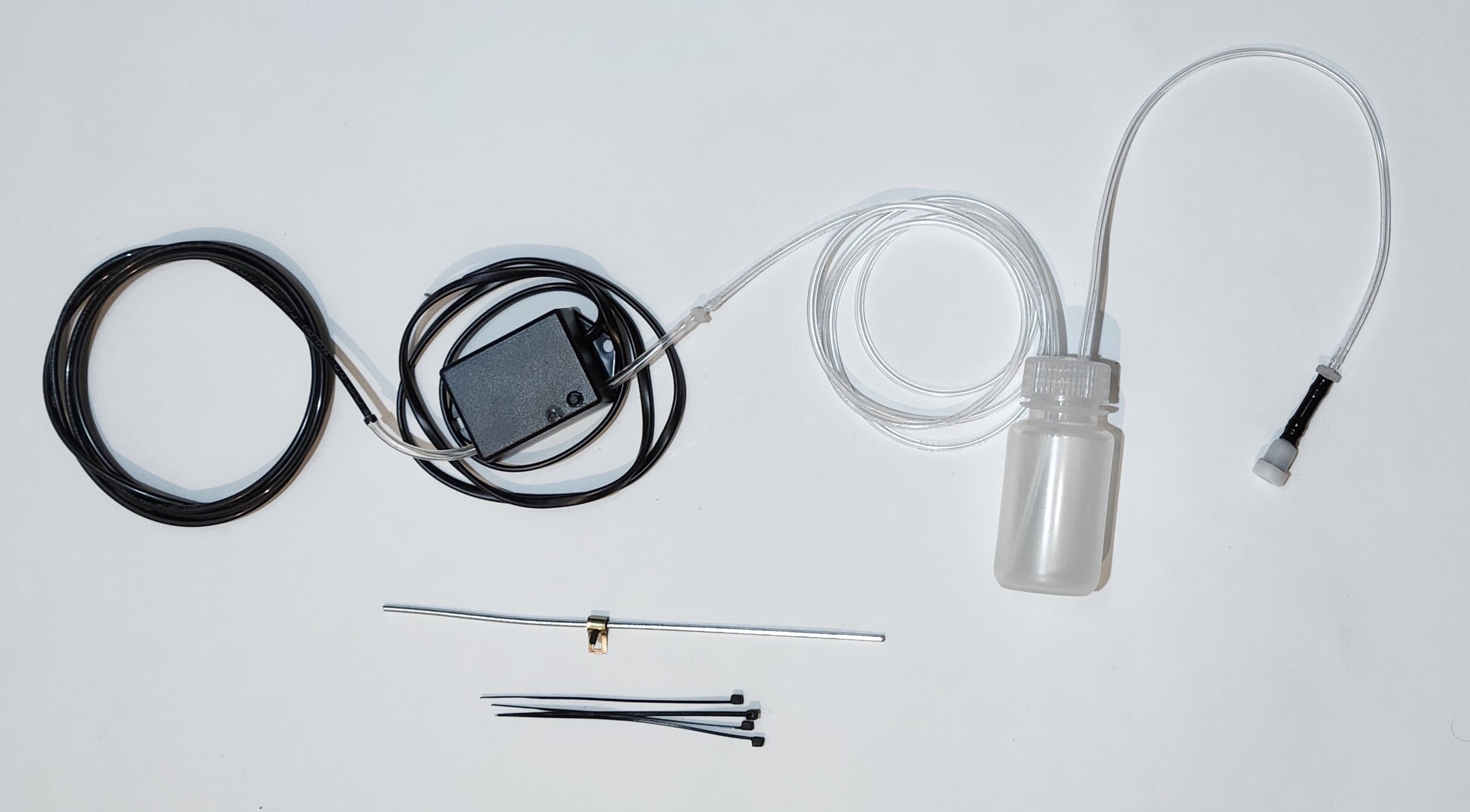

Oiler set - 60ml oil reservoir, controller box, dispensing hose and a steel wire to keep hose in place.

Plumbing

Electronics is only a part (maybe the least important) of the whole system. The issues of plumbing (oil container, venting, flow control, etc) and the final delivery onto the chain are just as important.

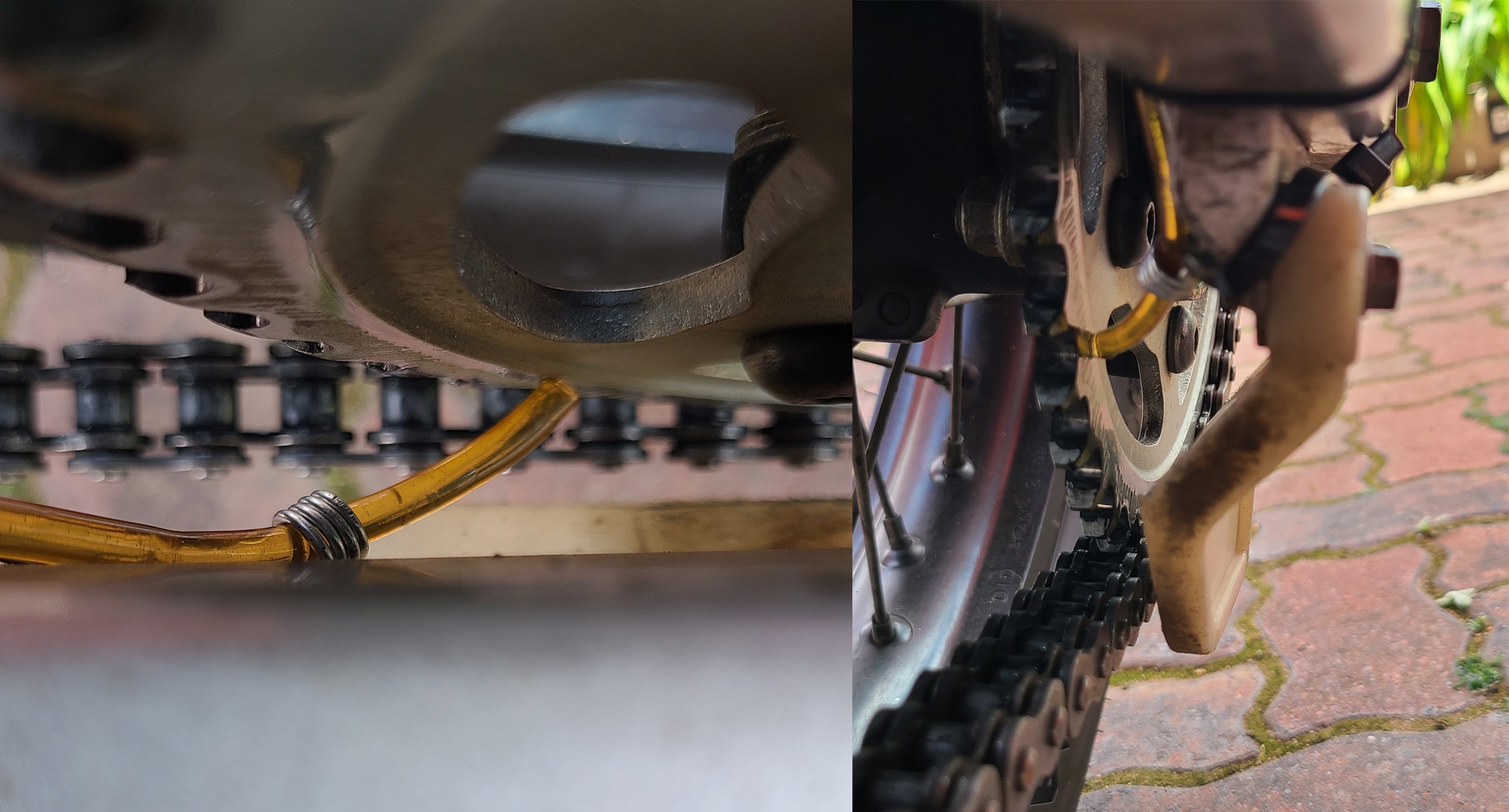

Ideally, oil should be dispensed only onto the chain and not anywhere else. Extensive testing has shown that the best method of transferring oil onto the chain is visa centrifugal force of the spinning sprocket. If the tip of the hose barely touches sprocket at 7 o'clock position, oil will get distributed failry evenly on both sides of the chain.

One version of the oil dispenser (onto the rear sprocket).

The system has to be robust for the challenges of adventure riding. Riding on gravel roads is not a problem. But rocky trails and dry washes may be a different story. During testing on Australia's Great Central Road and in washes of Utah we've had rocks kicked up by wheels sever plastic hoses and break off brackets holding the nozzle.

Simplest Set-And-Forget Oiler

Over the years various features were added and removed during testing. Bluetooth was probably overkill for such a simple task of keeping chain properly lubricated. Besides, during testing we found it awkward to stop the bike, pull out a smart phone, fire up the app just turn on or off the oiler. With a single button, one could turn the oiler on or off while riding.

Hose is securely held in position by a steel wire, which in turn is attached to the stock chain guard by zip ties. The whole assembly is hidden behind the chain guard so as to protect it from flying rocks.

Most motorcycles have either chain guard or some threading for bolts to secure chain guard near the rear sprocket. If not, a hole can be drilled in the swingarm and the steel wire can be held in place using a bolt and nut. Even without any tools, the wire can be secured by zip ties.

In the photo shown above, no special tools were used to attach oiler and dispenser to a Honda Transalp. Simple zip-ties were sufficient for a 20,000km journey on very rough roads of Southern Africa.

Counter-sprocket cover on this BMW F800GS has holes in it. The oil is delivered onto the counter-sprocket through the hose. Centrifugal force is responsible for the transfer of oil onto the chain. This final delivery point is suitable for mostly dirt roads or when the rider prefers oiler hose to be less noticeable.